crushing, screening, and material handling power your site needs

metso plant equipment

Metso offers a full range of crushing, screening, conveying, and washing equipment — from the Lokotrack® mobile series to Nordtrack™, HRC™ crushers, and fixed plant solutions. Designed for efficiency and reliability, Metso machines are used throughout New Zealand in quarrying, contract crushing, recycling, and sand production.

Whether you need a tracked jaw for hard rock, a cone setup for consistent end product, or a mobile scalping screen to manage changing feed, Metso gear is built to handle it. Their equipment integrates smart control systems, modular designs, and durable wear components to reduce downtime and boost productivity.

At MIMICO, we provide local access to Metso plant equipment, parts, and support backed by decades of industry experience and a commitment to keeping your operation moving.

lokotrack crushers

Mobile crushers for efficient on-site processing. Lokotrack units are built for high-capacity crushing with proven Nordberg® jaw, cone, or impact crusher technology. Designed to reduce transport and setup time while delivering consistent end-product quality.

nordtrack crushers

Compact mobile crushers ideal for smaller contracting jobs and rental fleets. Nordtrack crushers deliver reliable performance in concrete recycling, soft rock, and construction waste applications with easy transport and user-friendly operation.

Nordwheeler CRushers

Wheeled crushing plants engineered for mobility and high throughput. Nordwheeler crushers deliver efficient primary or secondary crushing of hard rock, concrete, or recycled materials, with plug-and-play operation and rapid setup for quarrying and contracting use.

lokotrack screens

Track-mounted screens that integrate easily into mobile crushing circuits. Lokotrack screens handle heavy-duty applications including scalping, classification, and precision sizing – all with quick setup and efficient mobility.

nordtrack screens

Mobile screening solutions built for productivity and simplicity. Nordtrack screens suit a range of materials from topsoil to aggregates, offering fast setup, intuitive controls, and flexibility for changing jobsite demands.

Nordwheeler Screens

Versatile wheeled screening units for aggregate and material separation. Nordwheeler screens combine reliability with mobility, offering high-capacity performance and compatibility with Nordwheeler crushers for streamlined multi-stage processing.

Fixed Screens

Heavy-duty stationary screening solutions for accurate separation and sizing. Metso’s fixed screens are customisable for coarse or fine screening, with robust design suited to demanding aggregate or mineral applications.

Fixed Crushers

Stationary crushing units engineered for high-volume throughput. Designed for primary, secondary, or tertiary stages, fixed crushers offer long-term performance and reduced operating costs in quarrying and mining operations.

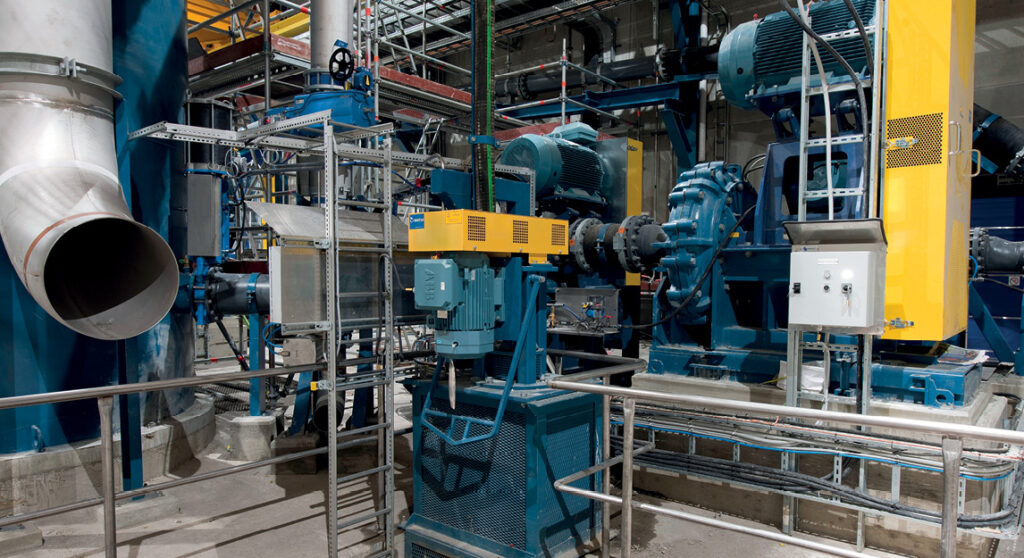

Slurry processing Pumps

Slurry handling solutions for abrasive, high-density materials. Metso’s horizontal and vertical slurry pumps are engineered for reliability in mining and minerals processing, supporting consistent material flow and longer wear life.

Flexible Financing for metso plant Equipment.

Our Full aggregates Lineup

Metso Material Processing Equipment.

Our complete range of material processing equipment includes mobile and fixed crushers, screens, trommels, shredders, conveyors, stackers, wash plants, and blending plants – providing reliable solutions for aggregate production, recycling, and material handling.

Why Choose Metso Equipment?

Total Plant Control.

Modular and Scalable Design

From single-machine setups to full plant configurations, Metso equipment is built to scale. Their modular approach allows for easy expansion, transport, and integration with existing gear — ideal for both permanent and mobile applications.

Optimised Wear Protection

Metso designs its crushers and screens with high-wear zones in mind. Replaceable liners, smart chamber geometry, and material flow modelling help reduce maintenance time and extend wear life — especially in abrasive or high-volume conditions.

Proven Fuel and Cost Efficiency

Metso mobile equipment like Lokotrack® and Nordtrack™ is engineered for reduced fuel consumption without compromising output. Smart power use, load-sensing hydraulics, and efficient material flow mean lower cost per tonne, every day.