| Screen Size | 4,860 x 1,520 mm |

|---|---|

| Screening Area | 7.4 m² |

| Decks | 2 |

| Hopper Capacity | 4.5 m³ (Standard), 11 m³ (Extended) |

| Engine Options | CAT C4.4, 75 kW |

| Weight | 26.0 t |

| Width | 3.0 m |

| Height | 3.56 m |

| Length | 15.4 m |

| Transport Width | 3.0 m |

| Transport Height | 3.56 m |

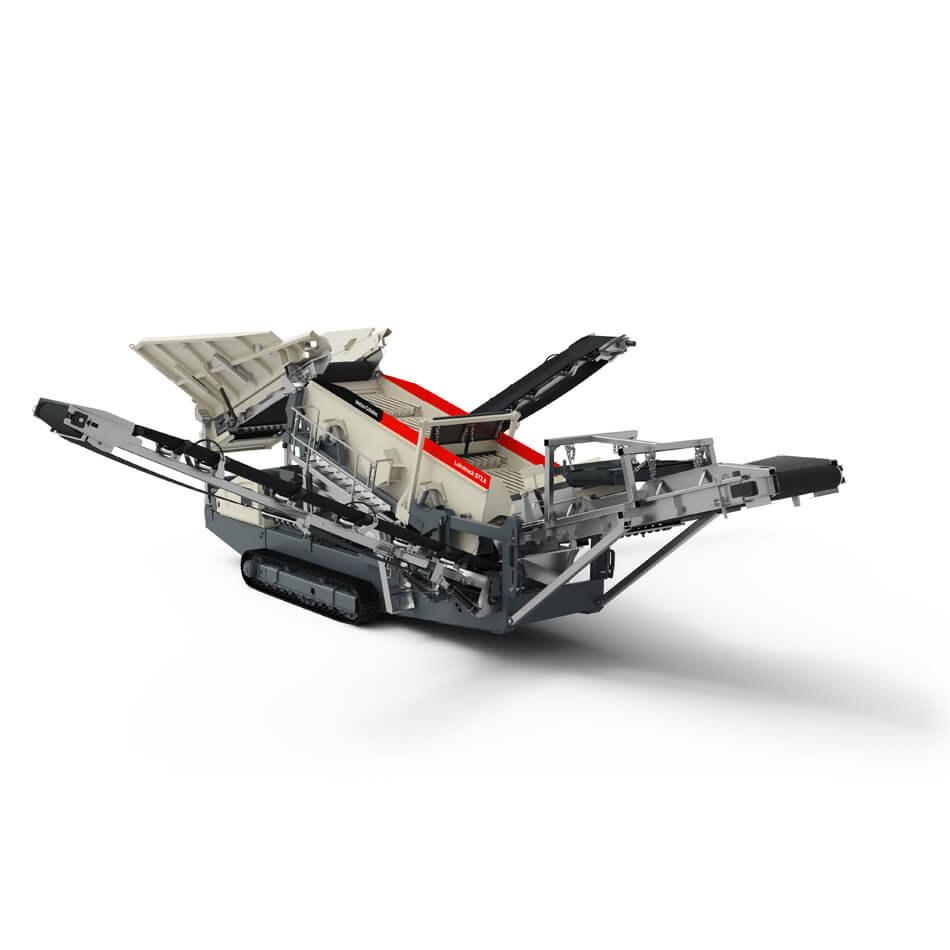

| Track Mounted | Yes |

Mobile Crushing & Screening Backed by Responsive Support

Decades of Crushing, Screening & Support Solutions

Check out Metso’s full lineup of crushers, screens, and wash plants – built tough for high performance and reliability on the job.

Sign-up to our monthly MIMICO newsletter.

No spam, we promise… because your inbox deserves better.